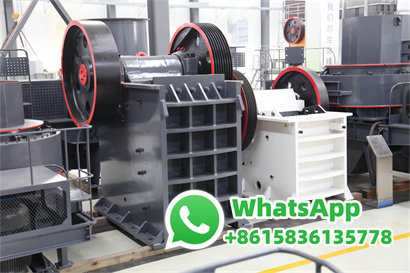

في مواجهة مشاكل مثل العرض غير المستقر للرمل والحصى والجودة التي لا يمكن السيطرة عليها، فضلاً عن التقدم المستمر لتكنولوجيا الخرسانة ومتطلبات المواد الصارمة بشكل متزايد لمشاريع البناء، تختار العديد من شركات الخرسانة التعاون معنا من أجل تحسين جودة الخرسانة. المنتجات الخرسانية وزيادة أرباح الشركات إنشاء ركام من الرمل والحصى عالي الجودة.

MAGNETIC SEPARATORS Will save that waste iron and screen your sand as well Our Type F Separators reciuire no shoveling Simply dump the material into the grizzly Note elevator feature Magnetic separator can be fur nished without this feature if desired thus reducing of Canadas largest foundries has just orden done Name supplied on

Electromagnets use electricity flowing through a coil structure around an iron core to create their magnetic field Because of this overhead electromagnetic separators allow greater control over the presence of its magnetic field By simply cutting the power ferrous material will be released giving an electromagnet an advantage over the use of a permanent magnet in some mining

Manufacturing a complete line of magnetic separators including suspended overhead magnets magnetic head pulleys sweepers and eddy current separators About Dings Magnetic Group Contact 4740 W Electric Ave Milwaukee US 53219 Phone 4146727830 Fax 4146725354

·The Reading Pilot Induced Roll Magnetic Separator is specifically designed for the highly selective dry magnetic separation of samples of dry granular materials As the machine represents a full scale cross section of a full scale production model direct performance comparisons and machine settings are possible

Alat ini digolongkan dalam induksi magnet separator/seconda ry magnet separator type Contohnya Dings Incuded roll Separator Syarat yang harus dipenuhi pada Magnetic Separator adalah Alat harus menimbulkan medan ma gnet yang 1

·Dings brakes are spring set electrically released motor brakes for mounting to NEMA C face motors Dings also has a complete line of brakes for mounting direct to metric motors MAGNETIC SEPARATORS Dings Magnetic Division; manufactures magnetic; separators for recycling bulk; processing construction etc See

·Factors in Selecting an Overhead Magnetic Separator co Dings magnetic group Type of Magnetic Separator Self Cleaning vs Stationary Electromagnets Self Cleaning Models Permanent Magnets Stationary Models Self Cleaning Belt Options Stationary magnets are used when tramp metal is rare in your process but must be removed

·The key component of the eddy current separator is the magnetic rotor which has a series of permanent rare earth magnets mounted on a support plate attached to a shaft The magnetic rotor is surrounded by a wear shell Dings magnetic group Concentric Design Magnetic Field Concentric Design Triple Layer Shell

·The Reading Pilot Induced Roll Magnetic Separator is specifically designed for the highly selective dry magnetic separation of samples of dry granular materials As the machine represents a full scale cross section of a full scale production model direct performance comparisons and machine settings are possible

·The key component of the eddy current separator is the magnetic rotor which has a series of permanent rare earth magnets mounted on a support plate attached to a shaft The magnetic rotor is surrounded by a wear shell Dings magnetic group Concentric Design Magnetic Field Concentric Design Triple Layer Shell

Magnetic Separator Murah bekualitas Agen Magnetic Separator Steinert Longji Longi magnetic Eriez Magnet Magnet Batubara Obral 7 Keunggulan Belt Weighing System BAS Turki Rp Harga aslinya adalah Rp Harga saat ini adalah

·Wet Drum Magnetic Separators Often used in the recovery of magnetic media in dense media separation processes Suitable for the recovery of fine magnetic particles Slurry High Intensity Magnetic Separators SHIMS High intensity fields generated in a slurry environment Used for processing fine paramagnetic materials 4 Dry Magnetic Separators

·Dings magnetic group Rotor Features & Design Dings Eddy Current Operation Material is fed onto the conveyor belt of the eddy current separator which moves it across the magnetic rotor where separation occurs The two streams of material discharge into a housing The housing has a splitter to divide the non

The Magnetic Separators is classified under our comprehensive Mineral Separator with a manufacturer for customized mineral separators allows you to tailor the equipment to your specific processing requirements Custom solutions ensure optimal performance and efficiency meeting your unique industrial needs

Advantages of a magnetic separator Magnetic separators are powerful portable and can be adjusted to remove various types of magnetic materials from a liquid or solid They are most effective when used in a liquid although it is also possible to remove solid impurities Magnetic separators are very versatile and incredibly simple in design

·In addition the development of high magnetic intensity reaching as high as T high gradient magnetic separators has been achieved with which it is feasible to economically separate non ferrous minerals copper molybdenum copper lead copper zinc separation During this period several magnetic separation technologies have been

Magnetic drum separators such as Dings Deep Draw Drums are another option for the remove of ferrous contaminants from wood and biomass product streams Their operation is similar to magnetic head pulleys although they are not part of the conveyor belt directly Instead material is discharged from the conveyor onto a rotating stainless steel

Manufacturing a complete line of magnetic separators including suspended overhead magnets magnetic head pulleys sweepers and eddy current separators About Dings Magnetic Group Contact 4740 W Electric Ave Milwaukee US 53219 Phone 4146727830 Fax 4146725354

·Dings magnetic group Powerful Magnetic Products Since 1899 Dings Company Magnetic Group engineering and sales staff work together from our Milwaukee WI factory to provide outstanding customer service from experts in magnetic separation We listen to our customers to gain an understanding of their needs and apply our

·pole change & high magnetic The off center eccentric magnet design of the rotor allows ferrous metal that made it past the upstream magnetic separator to be released from the belt as it leaves the magnetic area of the outer rotor shell This reduces the likelihood that ferrous metal will cling to field is the same as the 9100

·What is Magnetic Separation Magnetic separation is a method of using magnets to remove magnetic and ferrous materials from mixtures Essentially when a magnetically susceptible material is placed in a magnetic field magnets can exert magnetic forces on those materials attracting them closer while non susceptible materials remain unaffected

نحن نقدر ملاحظاتك! يرجى ملء النموذج أدناه حتى نتمكن من تخصيص خدماتنا لتلبية احتياجاتك المحددة.